System introduction

The reliability and health level of power plant equipment are the basis of safe production and economic operation. The equipment management of domestic power generation enterprises generally follows the principle of "prevention first, comprehensive treatment, planned maintenance". There are generally passive maintenance, overmaintenance and undermaintenance in practical work. On the one hand, the safety and reliability of equipment still need to be improved. On the other hand, it is far from the modern management standard of equipment asset's life-span efficiency and better cost. To realize the transition from preventive maintenance to predictive maintenance, state maintenance becomes an inevitable trend. To manage the equipment well, the equipment manager needs to know the operating status, health status and other conditions of the equipment, and gradually realize the optimization of the equipment. In order to realize simple and effective state monitoring of power plant equipment, after years of research and test, our company has introduced a power plant equipment pre-diagnosis system, which can realize remote monitoring equipment, remote data analysis, remote operation and maintenance, and realize the healthy operation of power plant equipment.

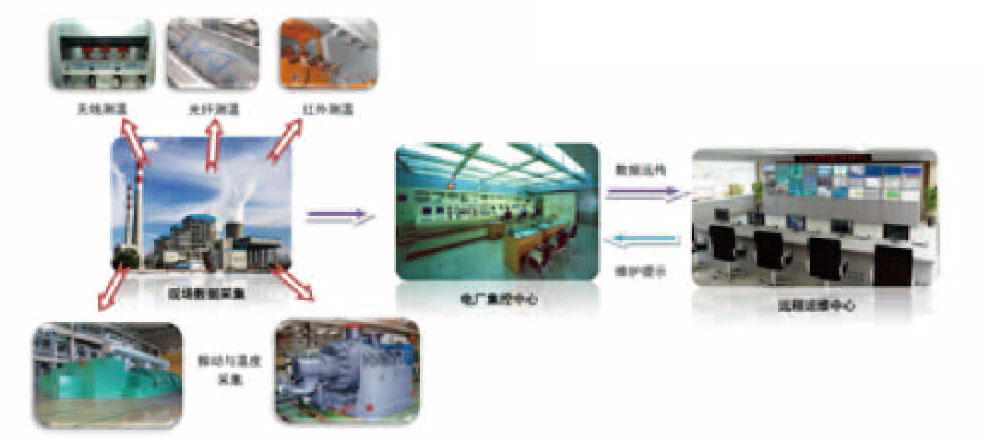

The system must be divided into: site data collection part, site monitoring part, remote maintenance part. The system diagram is as follows:

Schematic diagram of power plant equipment pre-diagnosis system

Field data acquisition part

The whole intelligent temperature monitoring system is the combination of the monitoring device and various sensors launched by our company. To provide users with high quality, cost-effective measurement and control integration device.

Function and characteristics of the device

● Integrated structure design, including: wireless temperature measurement, infrared temperature measurement, optical fiber temperature measurement, digital temperature and humidity measurement, PT100 thermal resistance, K-type thermocouple temperature measurement, vibration sensor, pressure sensor, etc.

● Intelligent operation platform, real-time operating system, can be combined by software to meet the requirements of all kinds of physical parameters measurement; The running status of each function module can be monitored in real time, and can realize self-check and self-repair function.

● Strong data storage capability. It can record all sensor measurement data for a long time and form XLS files, which is convenient for users to analyze temperature changes and establish cloud database.

● The device is equipped with GPRS module, which can realize remote monitoring and operation of the device, and the data can be uploaded to the remote server to realize online data analysis and recording.

Device parameters

● Rated power supply voltage: AC185 ~ 265V, DC110 ~ 375V;

● Temperature display range: -55~ 125°C; Humidity display range 0 ~ 99%RH;

● Alarm output contact power: AC220V/5A;

Communication mode: RS485, MODBUS communication protocol. Rs232-rj45 interface, ICE61850 communication protocol

● Data transmission: GPRS

● Host: full load, not more than 20W; Temperature measuring module: no more than 5W when fully loaded.

● Ambient temperature:

Work: -20 ~ +80C. Storage: -25 ~ +85°C, relative humidity is not more than 80%

● Device volume (H x W x D) : 175mmx 260mm x 180mm

● Screen opening size: 225mmx 171mm, through the mounting bracket (the product comes with) directly fixed the product on the panel.

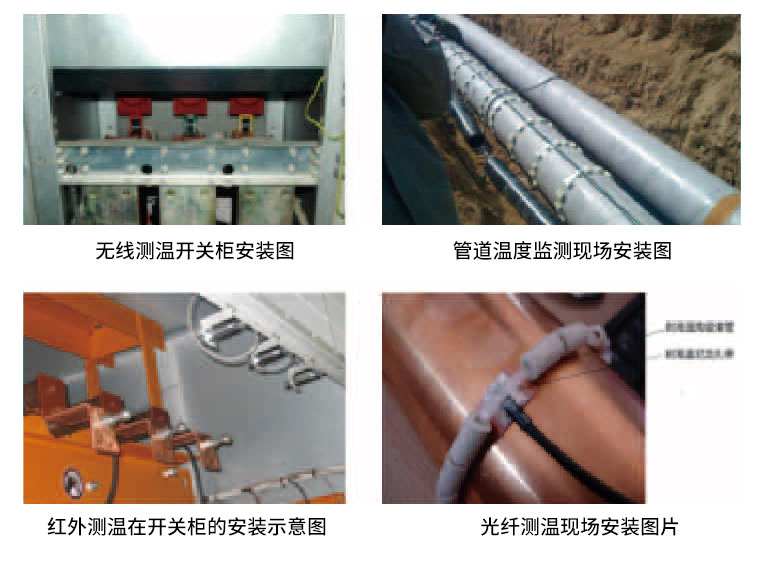

Field installation drawing

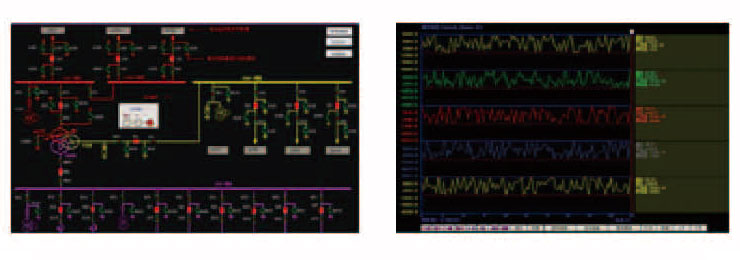

Monitoring part of centralized control center

● Real-time data monitoring to reduce the workload of on-site investigation by operators

● Remote data transmission remote operation and maintenance center, convenient for experts to remotely analyze problems, put forward the corresponding guidance scheme.

● Accept maintenance tips from remote operation and maintenance center, timely remind operation personnel of on-site maintenance.

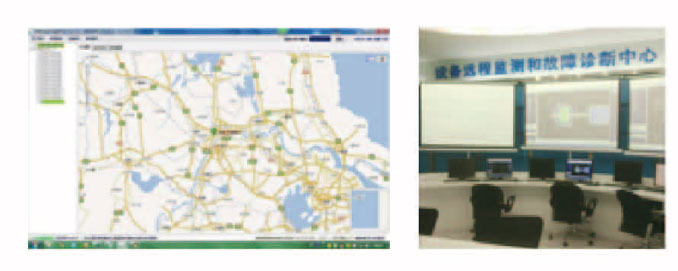

Remote operation and maintenance center

Equipment remote fault diagnosis service center is designed to provide users with remote professional diagnosis services, it is a fault diagnosis management platform, on this platform, equipment status monitoring and fault diagnosis is no longer limited by region and time. Through the interconnection with the equipment fault diagnosis center, users can obtain regular equipment status evaluation and fault diagnosis service at any time, and even when users are not aware of the abnormal status of the equipment, they can get the unit fault diagnosis report provided by the diagnosis experts. Through the Internet and mobile network, operators can control the operation status of key units at any time.

● Use the expert resources of the diagnosis center to solve the problems existing in the field equipment

● Support SMS hierarchical push

● Support offline data remote diagnosis

● Support online expert diagnosis

+86-312-5907779

+86-312-5907779

Home

Home Tel

Tel Product

Product